100-1000g Premade Bag Packaging Machine For Chip

The packaging system is including a Vibrator feeder, Z conveyor, Working platform, Multihead weigher,

Horizontal packing machine. With a blend of current packing

technology, reasonable design, and stable running, it is able to

pack various sizes of stand-up and flat pouches. Equipped with a

flexible processing unit, it can automatically be filling, sealing,

and do other packing processes. Premade pouch packing series is the

most optimum choice to realize economic and reasonable packing.

Feature

1.High weighing accuracy and efficiency.

2.Wide scope of application, Suitable for various materials.

3.Used in prefabricated bags, beautifully packaged.

4.Automatically complete all processes from feeding, weighing, date

printing to finished product output;

5.Used for the pre-made bag, Stable operation, high speed and high

production efficiency, beautiful bag making.

6.Stable operation, high speed and high production efficiency,

beautiful bag making, no leakage sealing and filling, effectively

improve the quality of packing machine in the material filling and

bag appearance.

Mechanical character

| Equipment model | JW-A13 |

| Equipment material | 304 stainless steel |

| Drive mode | Frequency conversion motor drive |

| Measuring type | Multi-head computer weigher |

| Operation interface | Touch screen |

| Bag materials | Heat sealable film as PA/PE, PET/PE, AL film, etc. |

| Filling range | 10~1000g |

| Packing speed | 20~55bags/min (depended on the product and filling weight) |

| Package accuracy | Error≤±2% |

Application

Suitable for weighing granules, slices, rolls or irregular shaped

products, such as candy, seeds, jelly, french fries, coffee beans,

peanuts, soft foods, biscuits, chocolate, nets, pet food, hardware,

etc.

Packing Pouch

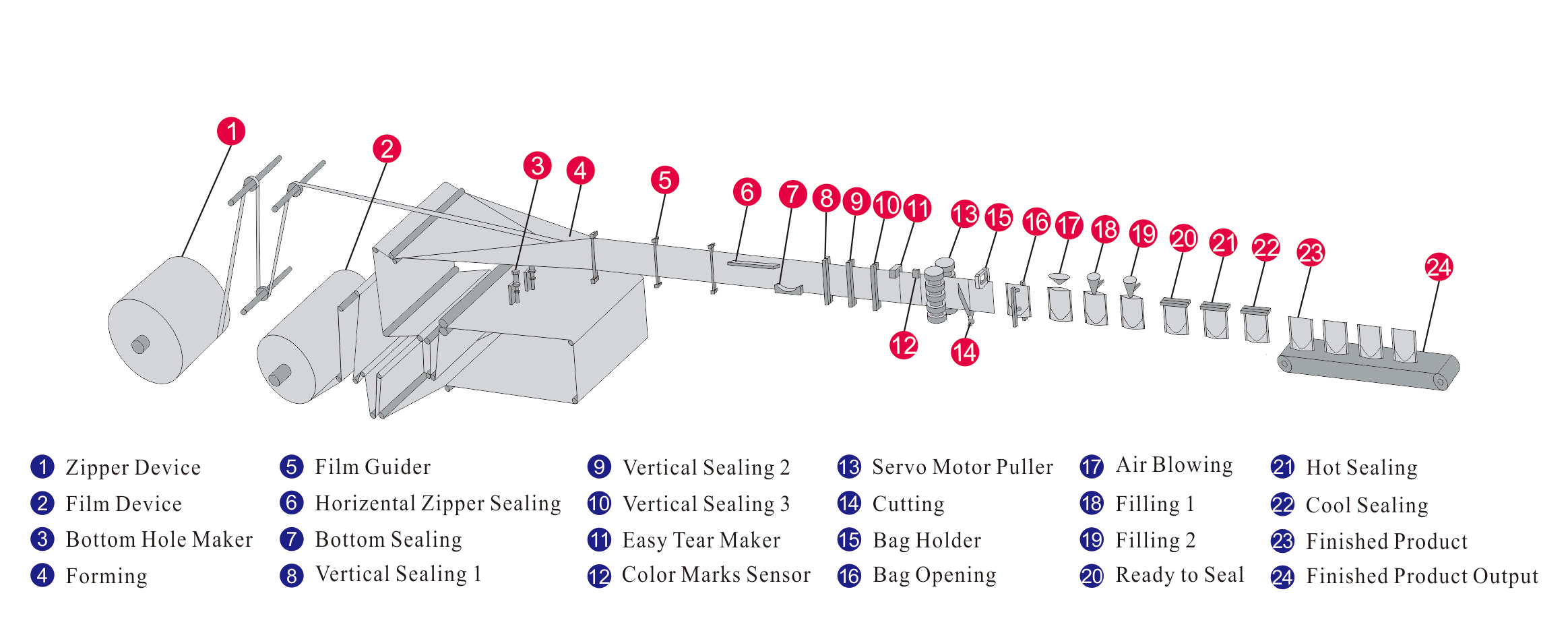

Horizontal pouch packing machine process flow diagram

Company profile

Specialized in the production of automatic weighing and packaging

machinery for 14 years, we devote ourselves to the complete

solution of automatic packaging. Now we become the professional

multihead weigher (linear weigher/check weigher/metal detector etc

) manufacturing enterprise with large production capability and

wide influence in the world. We have successively won the

“Guangdong Industry-University-Research Science and Technology

Project Award”, “high technology enterprise”, “Technology

Innovation Award” in the Chinese food processing and packaging

industry, Ringier Multihead Combination Weighing Technology

Innovation Award, a number of “Utility Model Patent Certificate”

and many other honorary certificates.

Having a high quality and R&D lab in the industry, our quality

department covers 16 inspection points such as incoming materials

checking, routing inspection, QE, pre-aging, and post-aging

inspection, finishing product inspection, and a complete quality

management system with restricted control of upper and lower

processes. Our products passed the environment simulation test,

frequency, waterproof test, salt spray test, amplitude, and elastic

stress-strain test, functional simulation test, 7*24 hours

continuous aging test, and so on. The core components such as

circuit boards and touch screens are all passed for nonstop aging

test for more than 72 hours at 50℃ environment because we devote

ourself to manufacturing craftsmanship products with high quality.

The failure rate of our products is less than 0.5% within 1 year

and less than 1% within 2 years.

Optional equipment:

Horizontal metal detector:

It is used to detect the metal which mixed during the production

process. It is suitable to use after finishing packaging (if

already equipped with other metal detector then no need use this

machine). |

Dropped metal detector: It is used to detect the metal which mixed during the production

process. It is suitable to use before packaging.It is installed

between weigher and packaging machine,space saving (if already

equipped with other metal detector then no need use this machine). |

Metal detector combined with check weigher: It is used to detect the metal and check weight,combined the check

weigher with metal detector,save cost and less commissioning and

maintenance time. |

Check weigher: Reject unqualified products, it can sort the product and make

statistics (if already equipped with other weight detection

equipment then no need use this machine) |

Rotary collecting table: Used to collect products from the production line,Suitable for

production lines that require manual processing or waiting for

further packaging operations. |